CRF Feeders

Unique feeders for pin headers

introduction

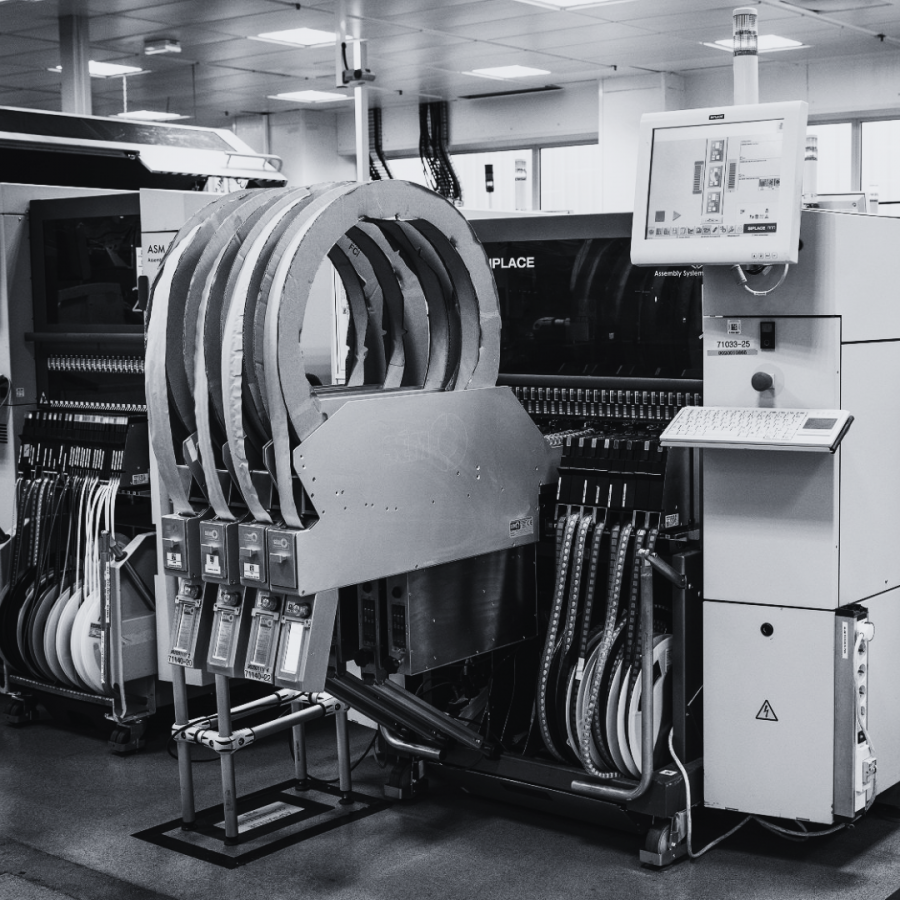

In addition to Tube Feeders, SEMO has developed feeders for delivering components in reels: the CRF (Cut & Roll Feeders). These standalone devices feed pick-and-place machines with pin headers, cutting them to the required length.

Pin header feeders tailored to your specific needs

Aiming to provide an efficient and durable solution for feeding pick-and-place machines, our teams designed the CRF to reliably perform the essential distribution functions.

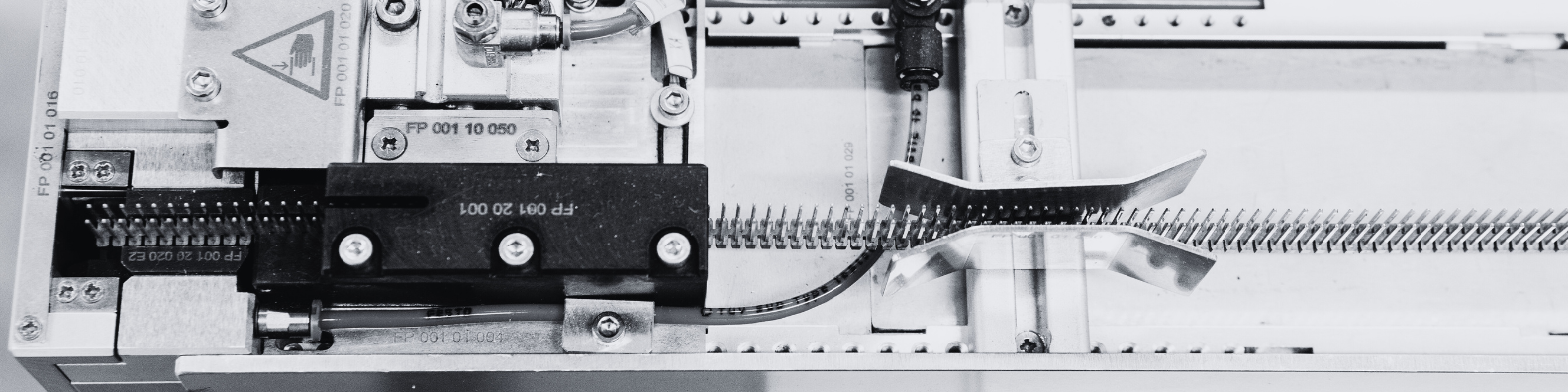

The component is brought to the cutting area by a movable gripper. A fixed gripper holds the component in place, and it is cut to a configurable length before the placement machine picks it up at the correct size.

Originally developed for distributing pin headers, the CRF is also suitable for handling components presented on laminated metal strips.

Reliability for high OEE

As the narrowest pin header feeder on the market, the CRF is very easy to install and use. The Cut & Roll Feeders are designed to minimize supply interruptions: knife or reel changes and reconfiguration for a new cut length, for example, can be completed in less than 6 minutes.

For increased productivity, the cycle time is 1 to 2 seconds. Ensuring quality, the feeding and cutting precision is around 50 µm.

Equipped with a touchscreen human-machine interface, our CRFs communicate with the placement machine on which they are mounted. Testing and maintenance can also be performed offline.

They can be installed on various machines and can interface both mechanically and electronically.