ZRF Feeders

Proven solution for custom requirements

introduction

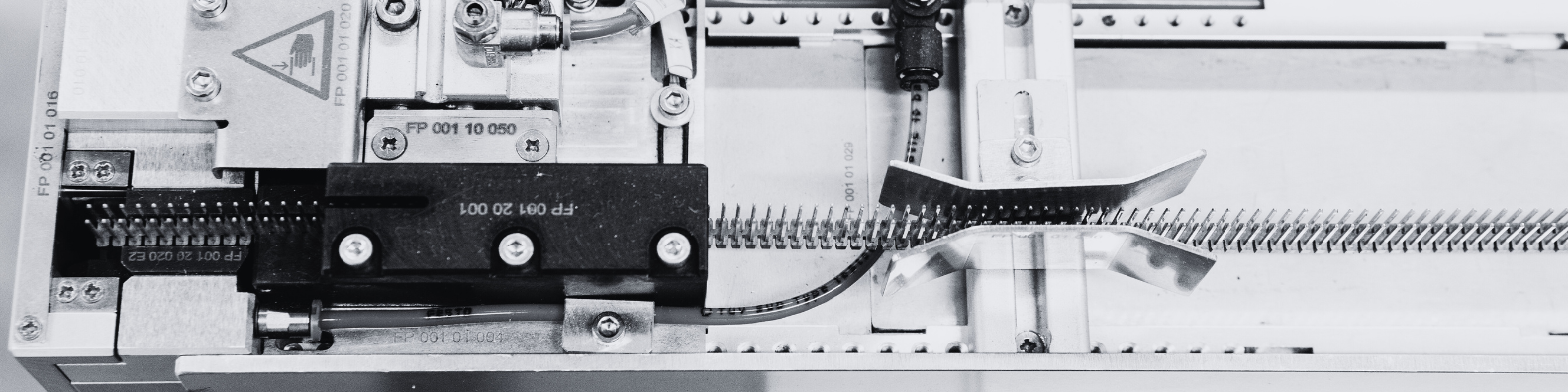

The ZRF feeder supplies pick-and-place machines with stamped metal components packaged in continuous reels. The ZRF feeder detaches each component from its metal strip and presents it to the placement head in the optimal position.

CUSTOM FEEDERS

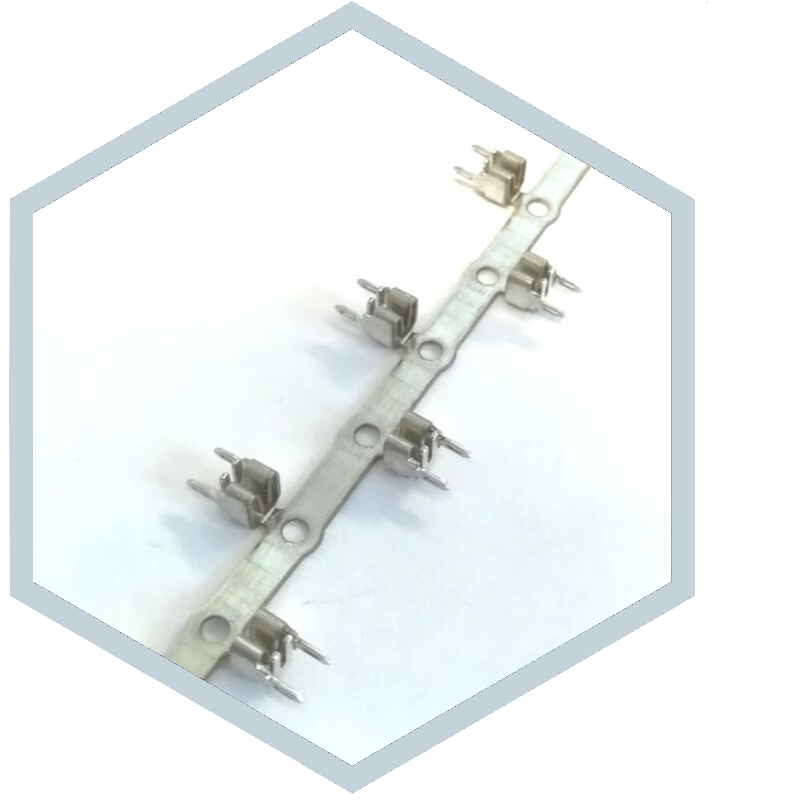

SEMO's ZRF feeder efficiently distributes components produced by stamping on metal strips and packaged in continuous coils. These components include tabs, quick disconnect terminals, test terminals, receptacles, cable connectors, etc.

These components and their reels are often very specific. The components regularly need to be rotated and reoriented to ensure optimal pick-up by the placement machine. The ZRF feeder is therefore designed to make these adjustments easily and meet customer requirements.

The remaining metal strip and any paper interleaving strip are returned and destroyed at the rear of the feeder.

TOOLING SKILLS TO ENSURE RELIABILITY

SEMO's ZRF feeder incorporates the functions necessary to ensure a high level of reliability: suction of the cutting area, intelligent communication with the machine, processing of the remaining metal strip, etc.

SEMO is a long-standing player in the field of cutting and bending tools. These skills are applied in the ZRF feeder for the preparation and presentation of components.