AF Feeders

The top of the range for axial components

introduction

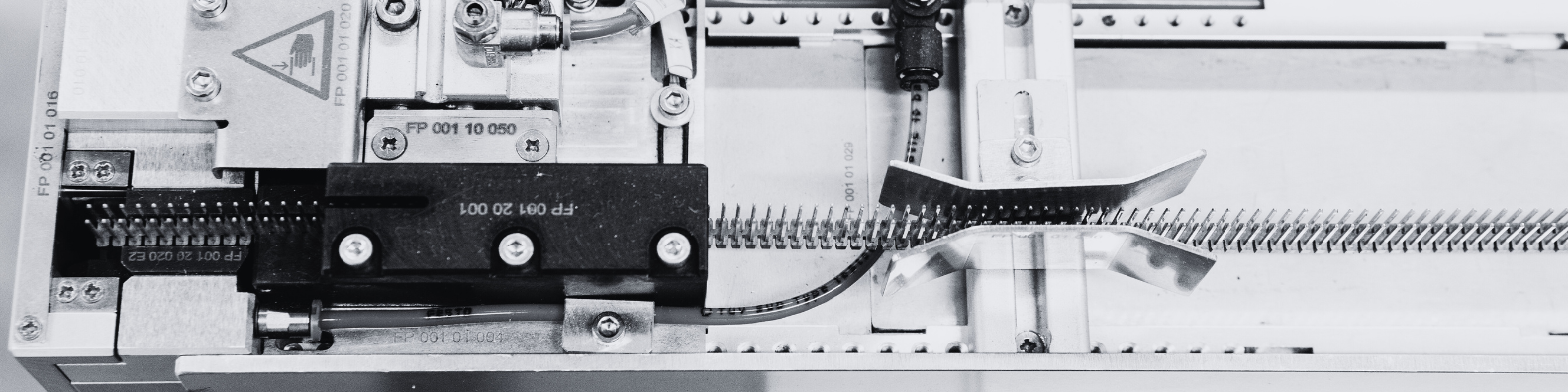

Once again, SEMO innovates and provides a unique solution for feeding axial components. The component is converted into an AF feeder outside the machine using one or two large-calibre cylinders. This concept, which is radically different from other solutions on the market, offers numerous advantages.

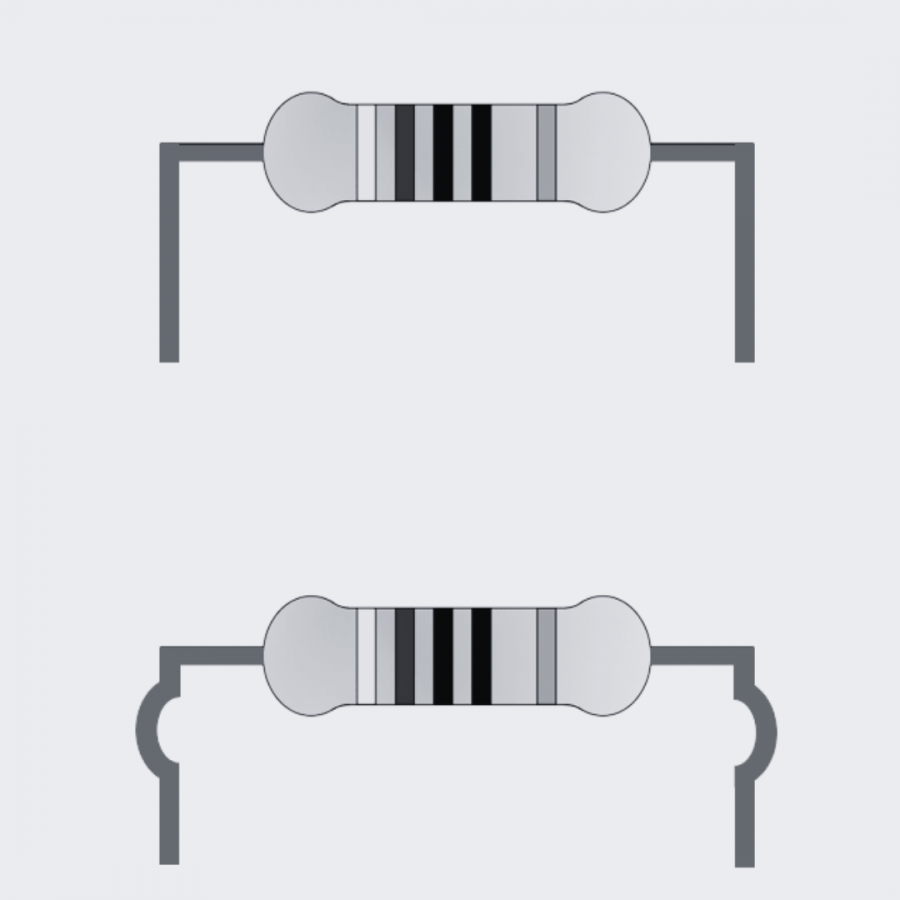

STRAIGHT LEGS OR WITH CURVES

The AF feeder can optionally shape the axial component before cutting it to length and bending it. Loops can therefore be added to each of the legs to ensure a distance between the component body and the electronic board.

All of these operations are performed outside the placement machine, ensuring a high level of technical cleanliness and easy access to tools, particularly for maintenance purposes.

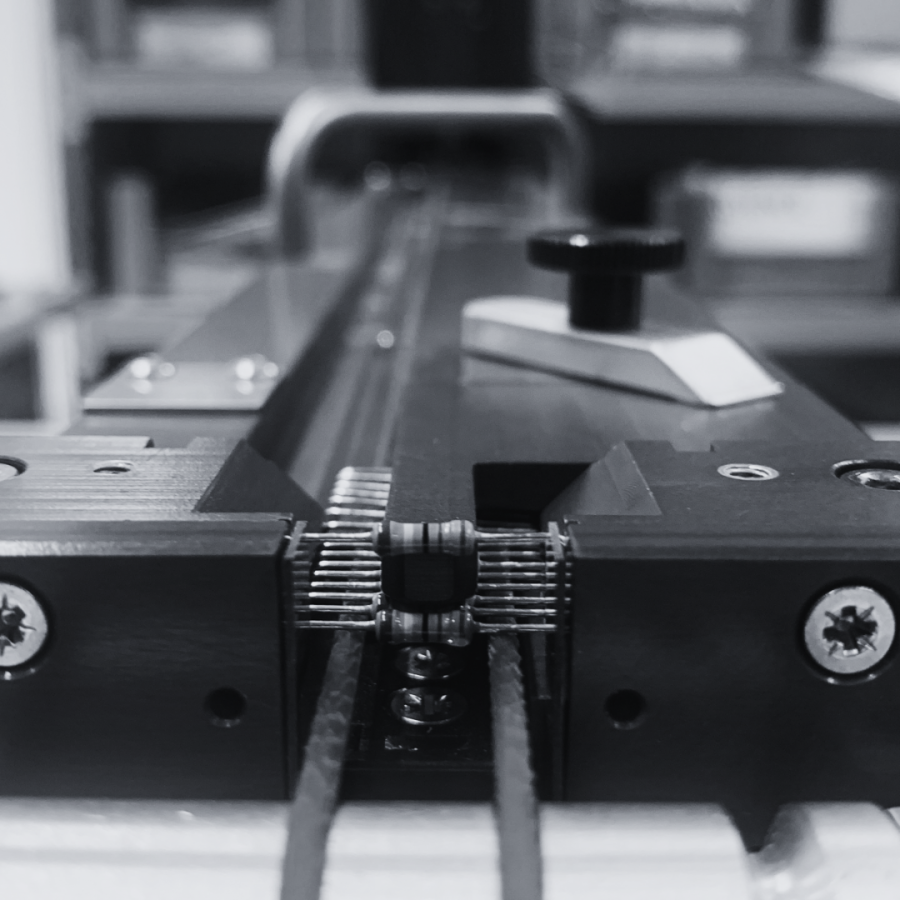

GUARANTEED LEG LENGTH AND ANGLE

Most feeders on the market bend the legs to less than 90° at best. Due to elasticity, the legs then reopen, resulting in an angle that is not 90° but more open. SEMO's AF feeder allows the legs of the axial component to be bent to more than 90°. This bend angle is adjusted to compensate for the elastic effect and ensure a final bend of 90°.

The size of the actuators and tools allows legs with a large diameter, for example 1.4 mm, to be processed.