References

Several hundred projects in the most critical applications!

introduction

With its commitment to quality workmanship and technical expertise, SEMO has been able to meet customer requirements in applications that allow for no failure or approximation. Here are a few examples of equipment designed and manufactured by SEMO. They illustrate the criticality and complexity of the applications addressed.

Automotive industry – Total control required for electronic integration

Automatic line with four stations for a global German automotive equipment manufacturer. The automated system requires perfect mastery of electronic integration processes, in particular metal laser welding for very small products (a few millimetres). The project also had to guarantee a clean environment, completely free from external pollution. A prototyping line was developed to validate the performance and reliability of the proposed solutions.

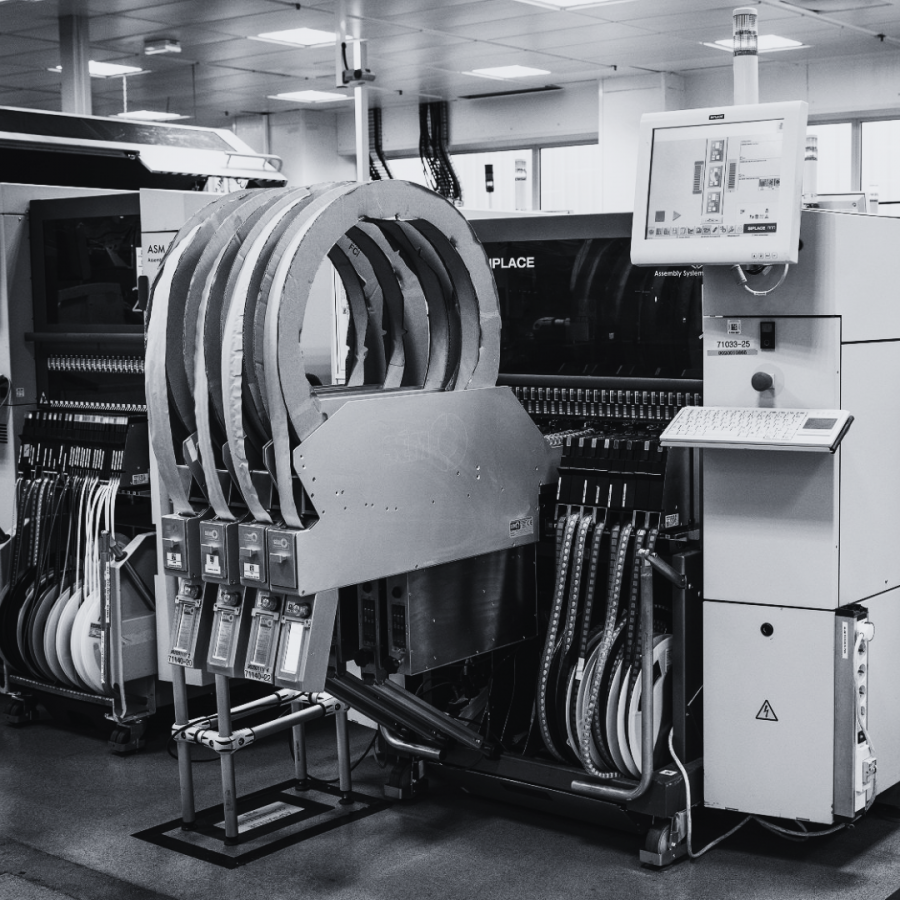

Electronics manufacturing – Proven solution for very high OEE.

Electronic component feeders for placement machines, for a global manufacturer of electronic cards, based in Asia and Latin America. With high speed (cycle time of 1 second) and flawless reliability (Synthetic Yield Rate >99.99%), CRF feeders are simple, high-performance devices that have proven their worth.

Space industry – quality and repeatability required for ‘zero defects’

Two custom-made pieces of equipment for a medium-sized company in the space sector, designed for assembling flexible materials. The ‘zero defect’ requirement inherent to the sector was imposed on these machines, which were developed and fine-tuned to achieve a high level of performance (quality and repeatability of assembly). Particular emphasis was placed on the strength and watertightness of the finished product, as the production process had to be repeated without distortion.

Defence industry – assembly for extreme conditions

Two special machines for a French global defence group, designed to manufacture critical electromechanical products requiring assembly precision of a few microns, for end use subject to extreme temperature and pressure constraints.

Medical Industry Sector – Continuous kinematics for high speeds

Machine for a global group equipped with cutting-edge technologies and using very high-speed equipment. SEMO used continuous kinematics technology, including several dozen servo axes, to provide a high-performance solution for forming and assembling a ‘flexible’ material at rates of several products per second. An innovative, very high-speed machine for a highly fragile product, the design of this equipment underwent a prototyping phase.

Automotive industry - LEAN concept with short cycle times

Line using LEAN concepts, consisting of four semi-automatic stations for a global American automotive group, comprising a series of assembly operations, including crimping and sealing, of electronic products with short cycle times. The line is ultimately intended for localised production in Asia.

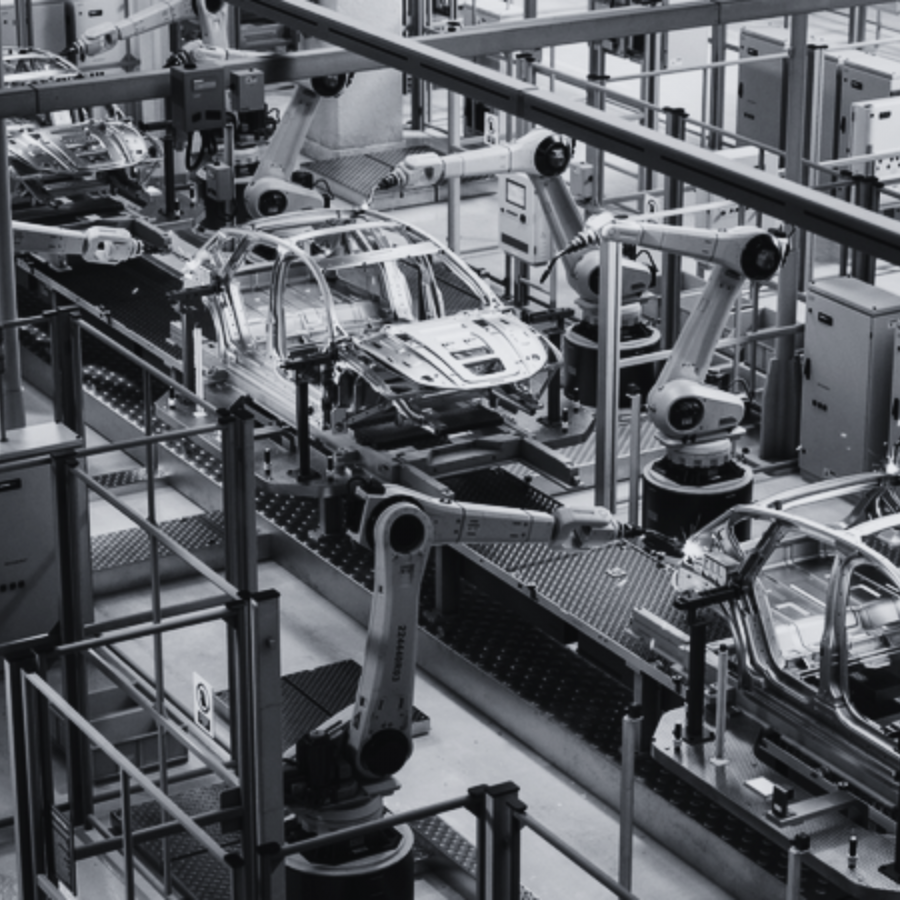

e-mobility – expertise in power electronics integration

Automated and robotised line for a global player in the electric vehicle industry. Production requires mastery of high-precision screwing, dispensing, laser welding and assembly processes for the manufacture of critical, high value-added sub-assemblies. High quality objectives, ESD constraints and cleanliness constraints were imperative.