SPF Feeders

AN INNOVATIVE SOLUTION

introduction

SEMO has developed recognised expertise in the production of reliable, high-performance Tube Feeders and Special Tube Feeders.

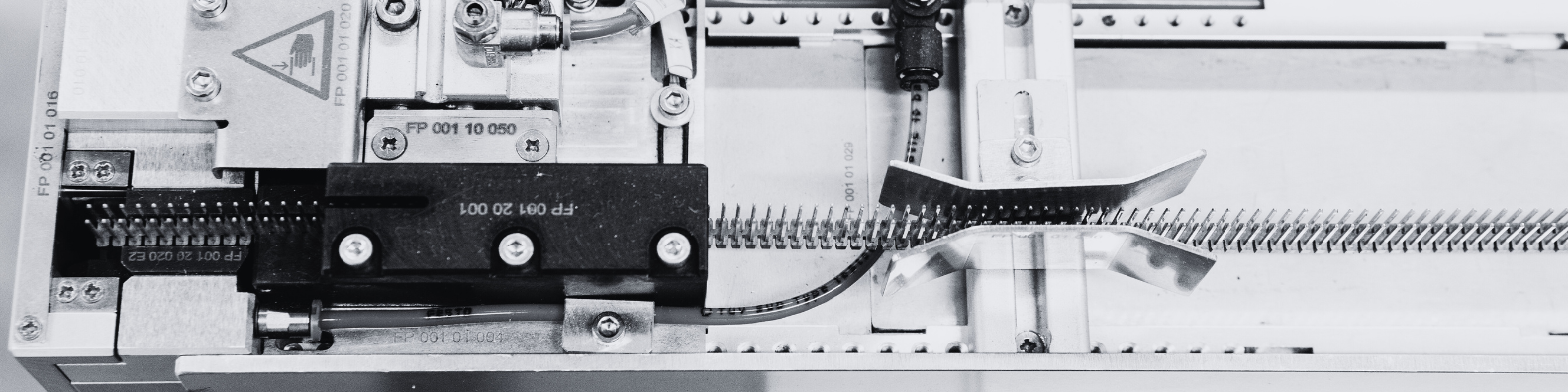

The SPF breaks new ground by enabling the processing of products packaged in pocket tape. This Feeder is capable of unwinding, cutting, forming and bending pins and electronic component leads before distributing them one by one to an electronic placement machine, known as a pick-and-place machine.

THE SPF FEEDER IS SUITABLE FOR PROCESSING PRODUCTS PACKAGED IN POCKET TAPE

SEMO's SPF Feeders are custom-designed, stand-alone devices developed to unload components packaged in blister packs and process them.

The integrated tooling is highly configurable and can perform up to three operations, such as cutting, bending, forming or trimming pins or leads on electronic components.

SIMPLIFY and improve the reliability of YOUR PRODUCTION LINES

Semo, which has always been able to carve out a place for itself in the precision tooling market, has now taken the gamble of leveraging its skills and expertise to integrate tools into its feeders. As a result, the feeders are capable of ‘processing’ a standard component. This saves you from having to purchase offline processing machines and handle products between machines. Finally, component traceability is ensured by the feeder and the pick-and-place machine.

TOOLING SKILLS TO ENSURE RELIABILITY

SEMO's SPF feeder incorporates the functions necessary to ensure a high level of reliability: suction of the cutting area, intelligent communication with the placement machine, processing of cutting waste, etc.

SEMO is a long-standing player in the field of cutting and bending tools. These skills are applied in the SPF feeder for the preparation and presentation of components.