RF Feeders

CHOOSE FOR VERSATILITY AND CUT REPEATABILITY

introduction

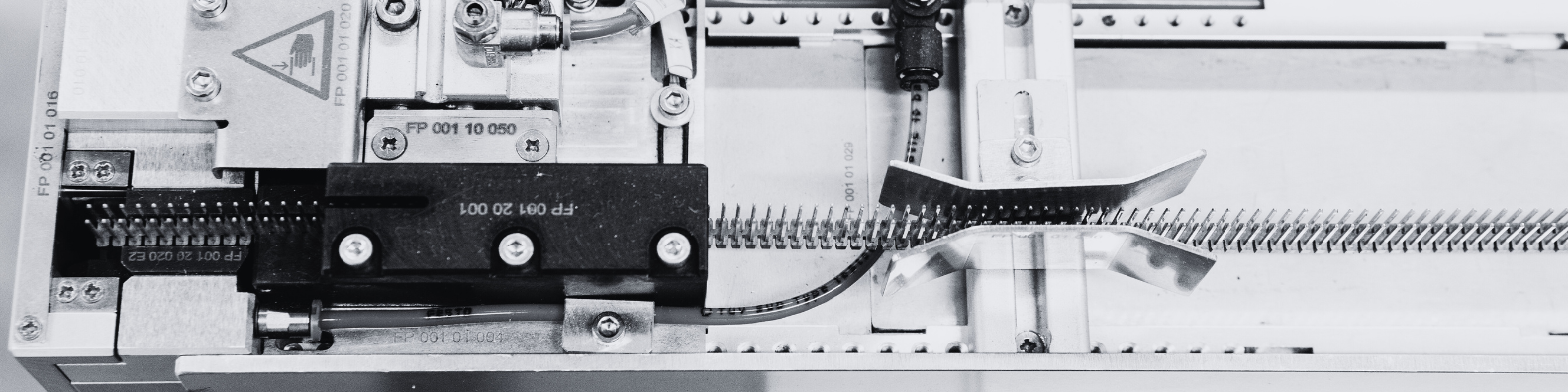

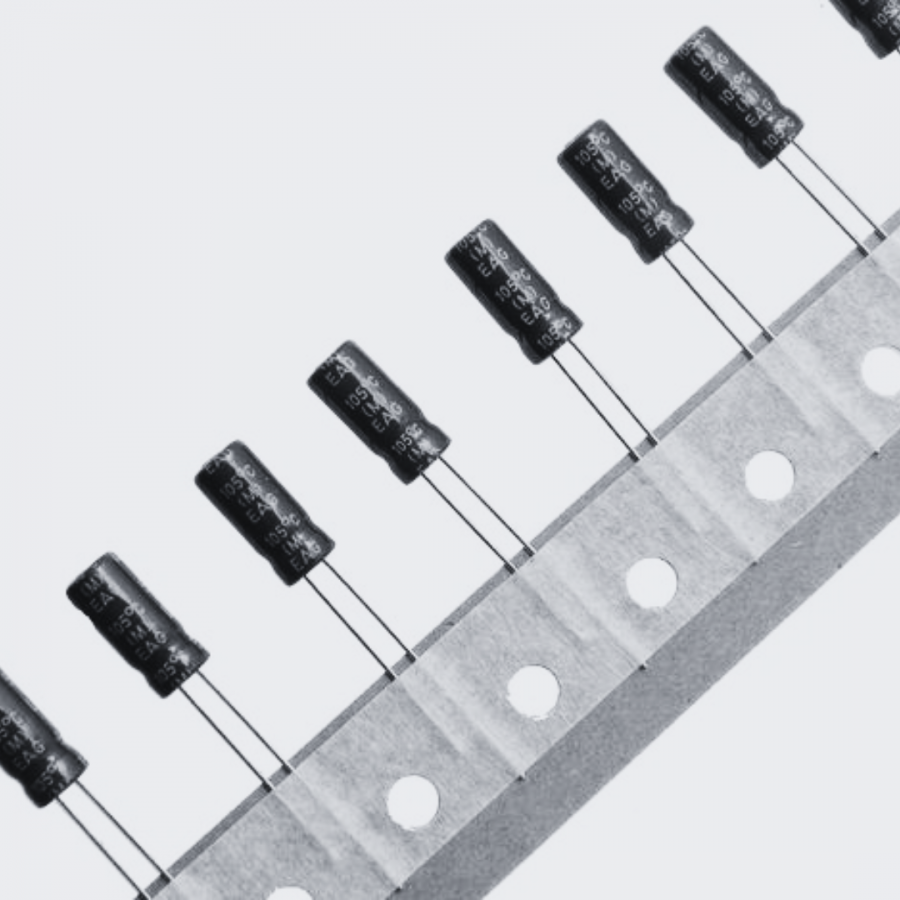

The RF radial feeder supplies your placement machines with radial through-hole electronic components packaged in tape and cut to length. It has been developed to provide a solution that is both extremely versatile and faithful to SEMO's tradition of robustness and precision.

VERSATILE FEEDERS FOR RADIAL COMPONENTS

SEMO's RF feeder is designed to adapt to many radial electronic components. With simple adjustments, the feeder can supply your placement machine with components that differ in tape pitch or pin position.

Depending on your needs, the RF radial feeder can be configured, adjusted and dedicated to a radial component. Alternatively, and only if necessary, the radial feeder can also be reconfigured and adjusted for multiple components using the SEMO portable IMH.

The range of options available makes this a very comprehensive feeder in terms of functionality, enabling you to maintain high OEE (interlocking, intelligent communication with the placement machine, suction in the cutting area, etc.).

Z-REF: HIGH CUTTING REPEATABILITY

SEMO offers the unique ‘z-ref’* function as an option. On an RF feeder equipped with this function, each radial component is mechanically referenced on the z-axis before cutting.

The cut is therefore not made in reference to the cardboard strip, which often results in very low repeatability and precision, but in relation to the component itself, thus ensuring highly repeatable pin height.

*patent pending