VF Feeders

BULK FEEDER: AN ECONOMICAL AND ECO-FRIENDLY ALTERNATIVE TO SPECIFIC PACKAGING

introduction

Some high-volume, low-mix parts are relatively small and inexpensive. In this case, blister pack packaging can be both costly (compared to the cost of the part itself) and harmful to the environment (lots of packaging waste). Bulk feeding can therefore be very useful: it is cost-effective and environmentally friendly.

HIGH-PERFORMANCE FEEDER FOR BULK PARTS

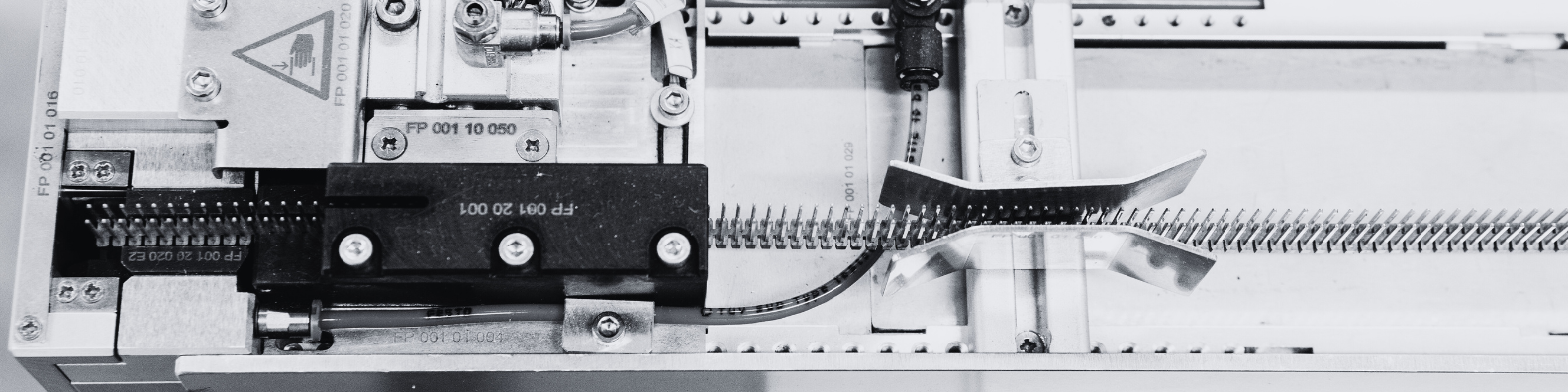

SEMO's VF feeder is a proven standard base that can be adapted to specific customer requirements. Depending on the part and cycle time, the VF feeder can be equipped with one or more bowls and one or more feed lanes. In the latter case, each lane includes a separation system so that each part is clearly separated from the next for clean and easy gripping. The speed of the feeder depends on the design of the part and can be as low as less than 0.5 seconds per part.

The VF feeder is designed and built by SEMO with machined and treated mechanical parts for all critical components. It can be equipped with several optional features such as low level alarm, cleanliness improvement, etc. for optimal production performance.

A COMPACT AND FLEXIBLE SOLUTION

The VF feeding solution takes into account the performance requirements for optimal production. The feeder uses limited space on the table: typically 120 mm wide, even for two lanes. The feeder therefore leaves plenty of space for other feeders.

In addition, the VF feeder is equipped with a re-centring and locking mechanism that allows the feeder to be removed from the table in the blink of an eye and reliably replaced on the table.