Integration of industrial robots

Indispensable to factories !

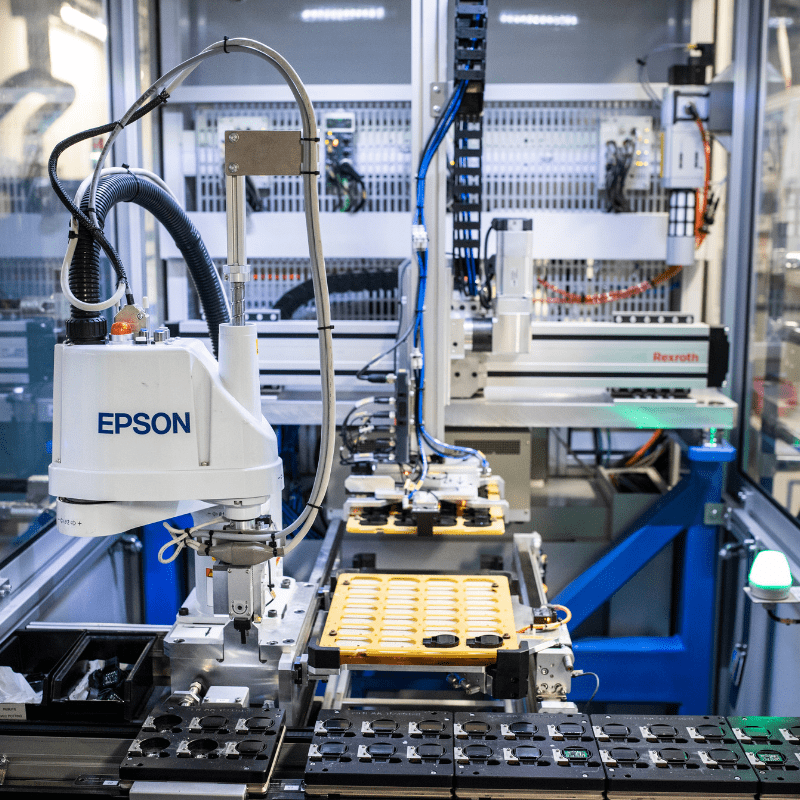

Often mentioned as a key lever of the current industrial revolution, industrial robotisation has experienced significant development in industry. Principally used by major automative groups, industrial robots are becoming indispensable in both small and medium-sized companies. SEMO has undertaken numerous integrations and has thus mastered the specific mechanical technology and software required for the successful implementation of robots.

What are the different types of integrated robots?

In the course of numerous projects, SEMO has familiarized itself with a myriad of robots. Robotic solutions consist of a 6-axis (polyarticulated robots) or a 4 axis (SCARA robots) arm mounted on the ground, fixed to partition walls, or suspended from the ceiling of the structure with a controller, a HMI and a gripper.

What are the keys to successful robot integration?

SEMO can tie vision systems to robots as well as include suitable solutions for product loading: bowl feeder, 3-axis vibration feeders, palletizing systems, etc

SEMO thus handles the complete integration of your robotic cell:

- Computerized 3D simulation of pathways and optimization of cycle times.

- Vision and feeding feasability studies

- Calculations and mechanical studies, in particular for grippers

- Robotic programming and associated vision options

- Safety studies and automation programming

- Assembly, cabling, wiring, finetuning and debugging

How does SEMO ensure the safety of your operators?

Some integrations require several robots to share common areas. They can also include zones with both robots and machinists working together which is known as man-robot cooperation.

These applications require knowledge of the safety standards, in particular the guideline "Machines" 2006/42/CE and the ISO standards 10218-1 and ISO 10218-2. A comprehensive risk analysis is formalized in order to guarantee the safety of production staff. All of our integrations meet the most recent manufacturing industry standards