Indexed systems

The Simplicity of a proven solution

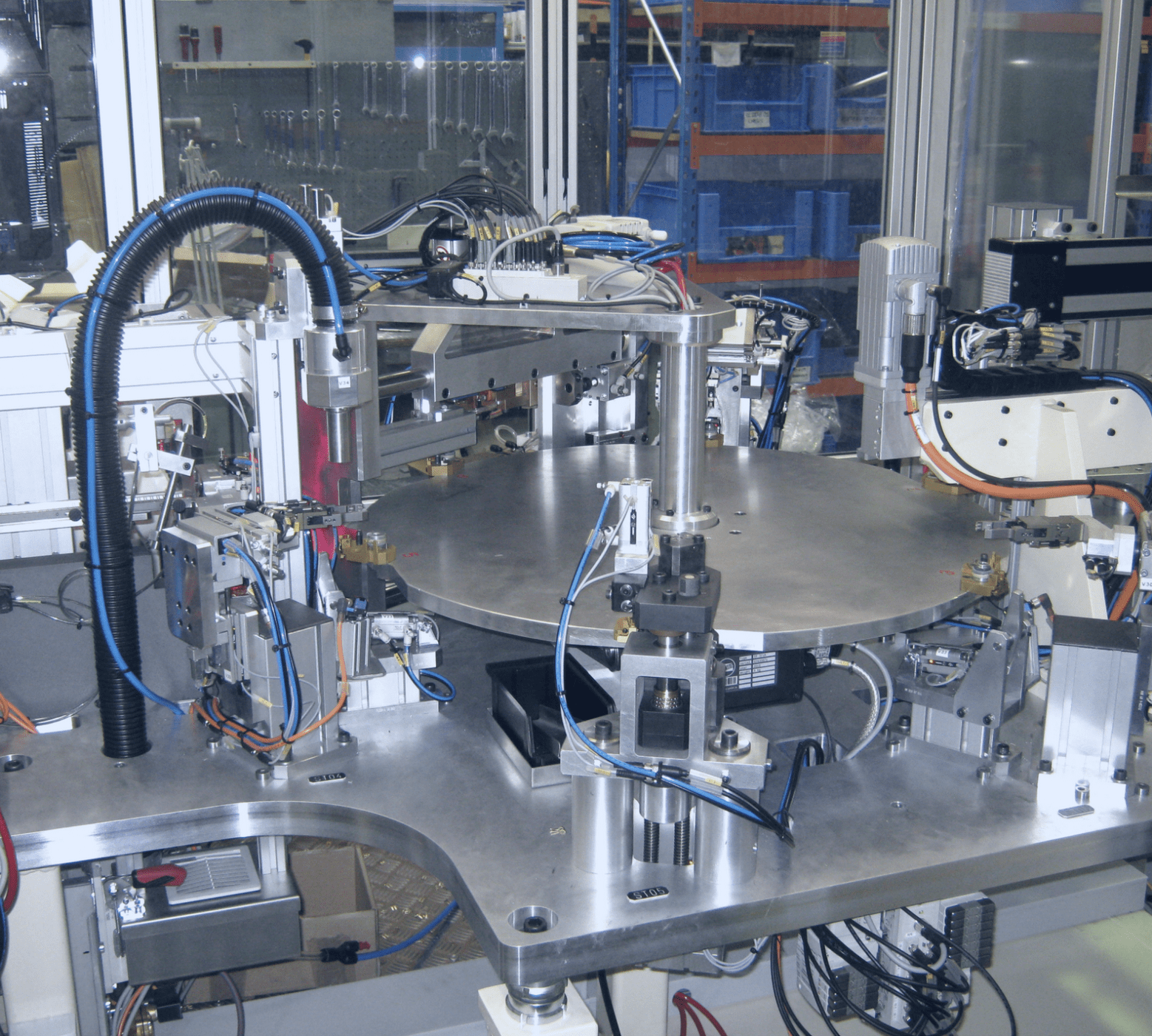

SEMO engineers and manufactures stations with indexed tables. This simple yet productive architecture has demonstrated its effectiveness in production that requires precision and high operation speed.

When would you choose indexed systems?

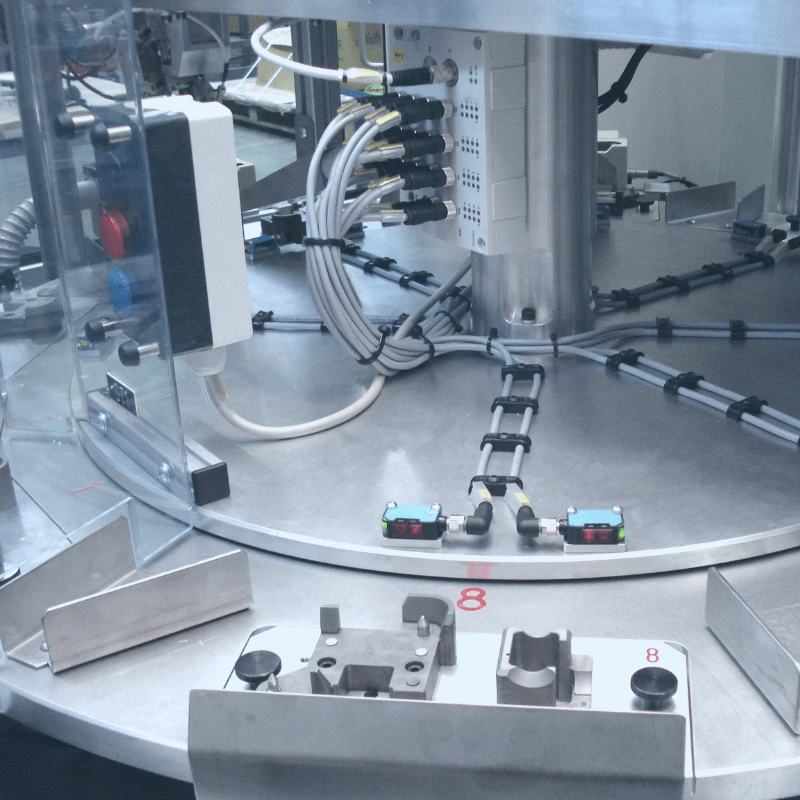

The indexed systems are generally based on a rotating table with upto 48 positions, each of them corresponding to a process station. The transfer time between stations is both short and smooth.

Alternatively, these systems can be linear tables, known as 'drawers', which allow for the loading and unloading in masked time.

This type of system suits precise and high speed automatic or semi-automatic processes. Different processes can be integrated into the same machine, such as riveting, screwing, crimping, pressfiting, etc...

What are the benefits of indexed systems?

This robust architecture allows parallel processing in restricted spaces. The short distance between each station results in transfer time of less than a second and ensures high speeds. Indexing products at each station ensures precision placement to hundredths of a milimetre depending on the size of the table. The architecture of the indexed table provides good durability and excellent reliability.

Our recognized know-how in this field ensures:

- The safety and usibility for operators

- Proper sizing of the indexing system after calculation of inertias

- Correct product positioning by the control of large tables warp.