Line SCADA

A "Must" for the most demanding industries.

In today's most demanding industries, quality and productivity go together. Reaching the expected levels of performance often requires adopting new approaches. The solutions offered by industrial IT help to overcome substantial hurdles in terms of industrial performance.

Quality: guarantee of quality and compliance of products.

Continuous improvement: instant visibility of results and highlighting of areas for improvement.

Productivity : central management of production flows

Durability: maintenance optimization

Line SCADA for better quality control

SEMO SCADA systems incorporate the most advanced quality features. They can oversee the serialization of products and thus the traceability of operations being carried out: the storage of data for each serial number and for each stage of production.

In addition, the management of interlocking between machines insures the completeness of all of the operations. This function guarantees that components and tooling match with the product reference to be produced.

Production SCADA systems for increased productivity

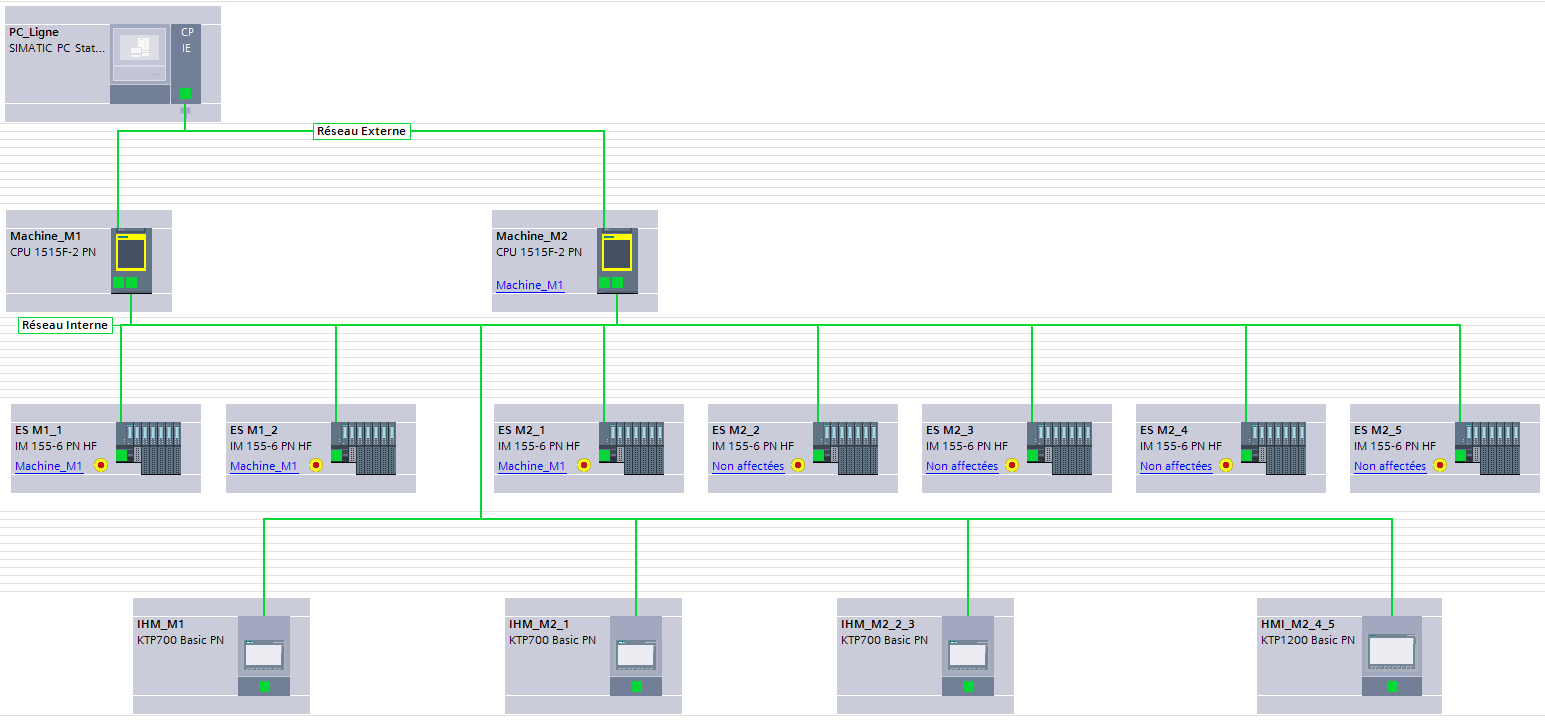

A genuine mastermind behind your production line, the monitoring is connected to machines or devices establishing the line. The lines server or PC provides a comprehensive overview of the performance of each machine and associated controls. Any detrimental processes or transfers can thus be identified and dealt with. Line monitoring also allows for central updating of routines and product changeovers, which can therefore be executed in a faster and sleeker manner. Finally, via performance indicators collected by the SCADA system, the user can program their preventative or predictive maintenance operations.

SEMO SCADA systems can be connected to your MES or to your ERP.