Deep Learning

ARTIFICIAL INTELLIGENCE FOR COMPLEX INSPECTIONS

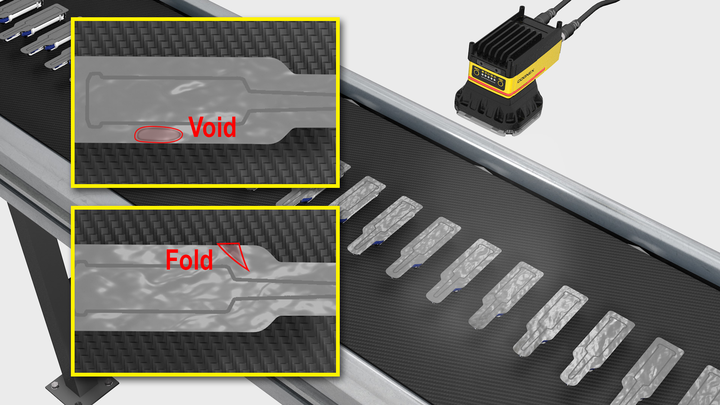

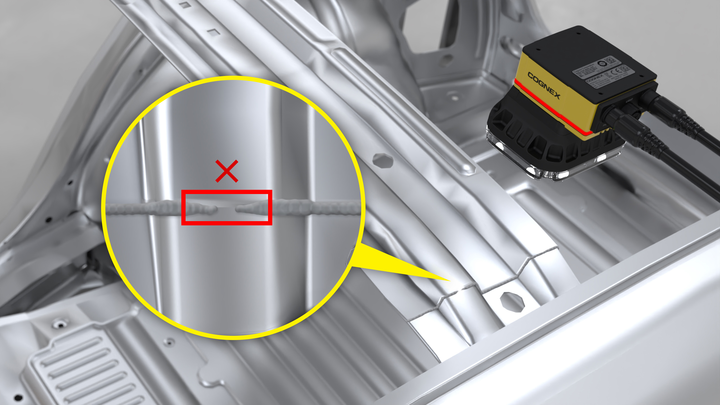

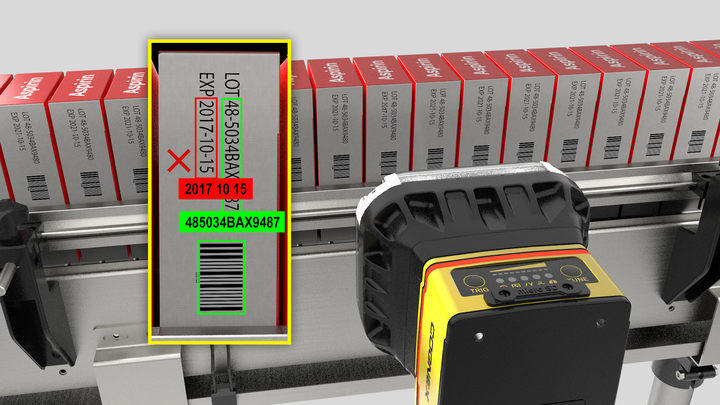

Traditional 2D vision has limits in the applications that can be programmed. Deep learning makes it easy to overcome this problem by creating a solution based on learning. The goal is to show examples (samples) of what we want to characterize and the VIDI software transforms these examples into a robust vision application. It's a bit like showing a child several pictures of a car so that he can recognize them by himself in the street after having seen a few examples.

WHEN TO USE DEEP LEARNING?

Deep learning is used to replace operations where the human eye excels: subjective or complex applications. Deep learning is not capable of measurement (fortunately, traditional vision is there for that) but it is perfectly adapted to control aspect, object recognition and classification of defects.