Heat staking

Heat staking enables the assembly of two or more pieces with atleast one being plastic. The process consists in distorting the plastic by heat and force for a set time. Assembly is achieved by partially distorting the plastic part with the help of a formed hot riveting die to match the other part.

When is it appropriate to choose heat staking?

This assembly process allows temporary mechanical bonding and is used during a given period of time before the dispensing of a seal, the potting or is used on the parts that are moderaly stressed (brand logo, aesthetic parts, control panel ...).

It is typically used in low-cost/high volume applications for example in the construction of automobiles, computers and of electrical whitegoods. We engineer and produce snap riveting systems integrated in a dedicated station which combines:

- the PLC system,

- the specific tooling for products

- and the heating system

Our technical knowledge of the three types of heat staking:

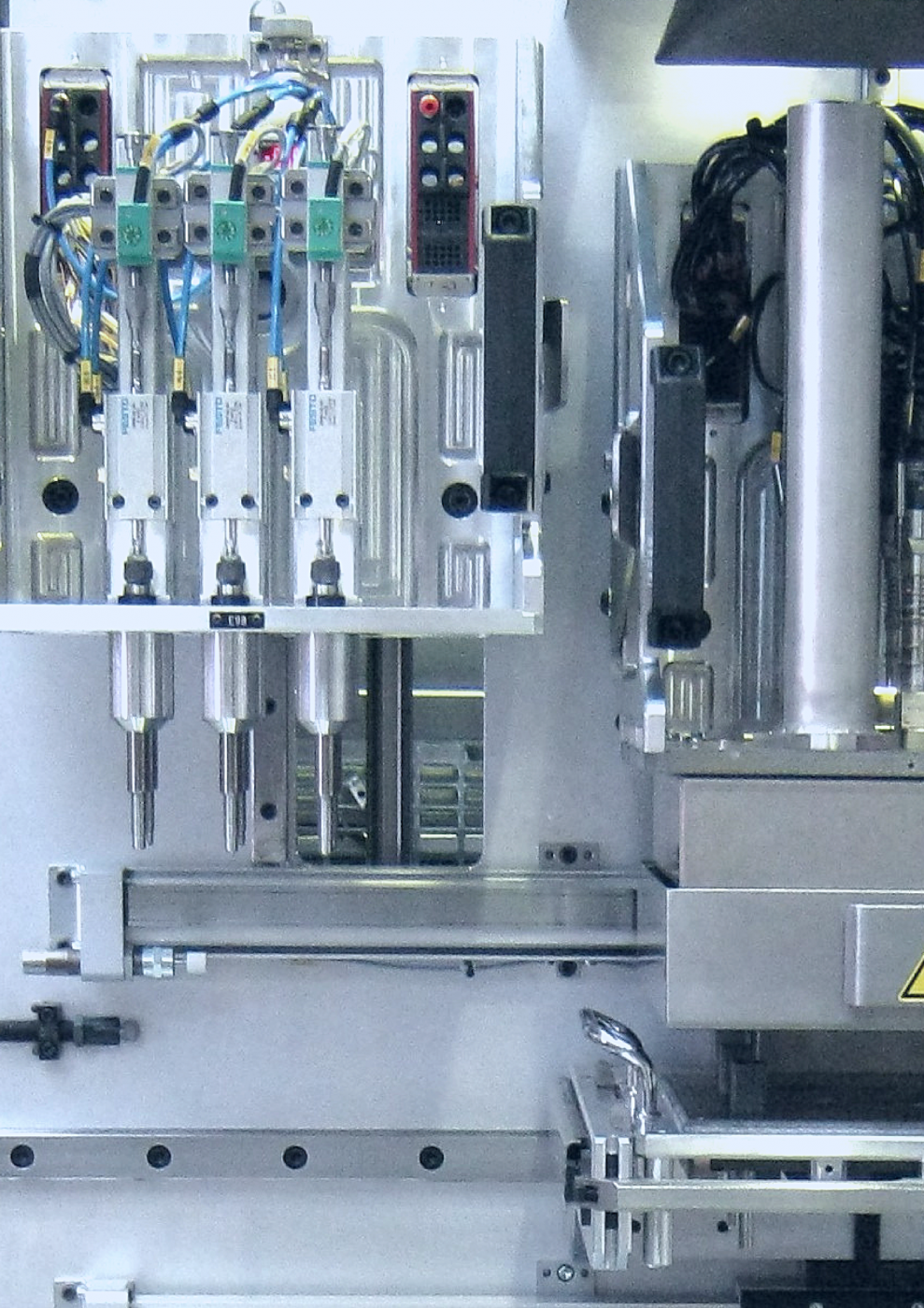

- Heat staking performed with hot riveting dies (each riveting die being thermo-regulated independantly or riveting dies heated via a heating brick)

- Heat staking as per ""Cold riveting die"". In this case, the plastic material to be riveted is heated beforehand by hot air or halogen lamps, then distorted by the cold riveting dies with (direct or indirect) height control of the latter. This process is called "Hot Air Riveting".

- Heat staking using thermode as per Miyachi process.

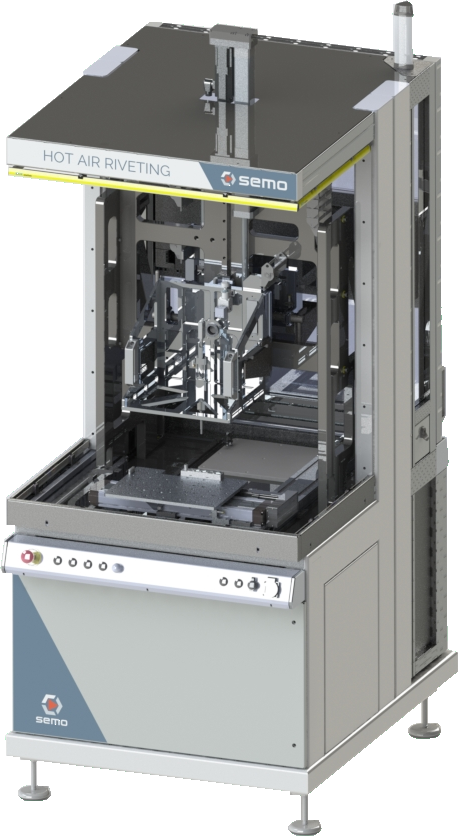

Our offer: Hot Air Riveting Versatile Machine

We have developed a standard machine that integrates the hot air riveting process, fully automatized and already parameterized. Only information concerning your assembly will be necessary to launch the process.

This machine is versatile: it adapts to any type of production line, from small to large series. You can therefore use the same machine for prototyping and then launch a production run simply by setting the parameters according to your needs.

Its versatility also allows it to be easily installed in the heart of an existing automated or semi-automated line.

This standard station is adaptable to the other solutions for electronic integration that we offer:

- Dispensing & Potting

- Pressfit

- Soldering