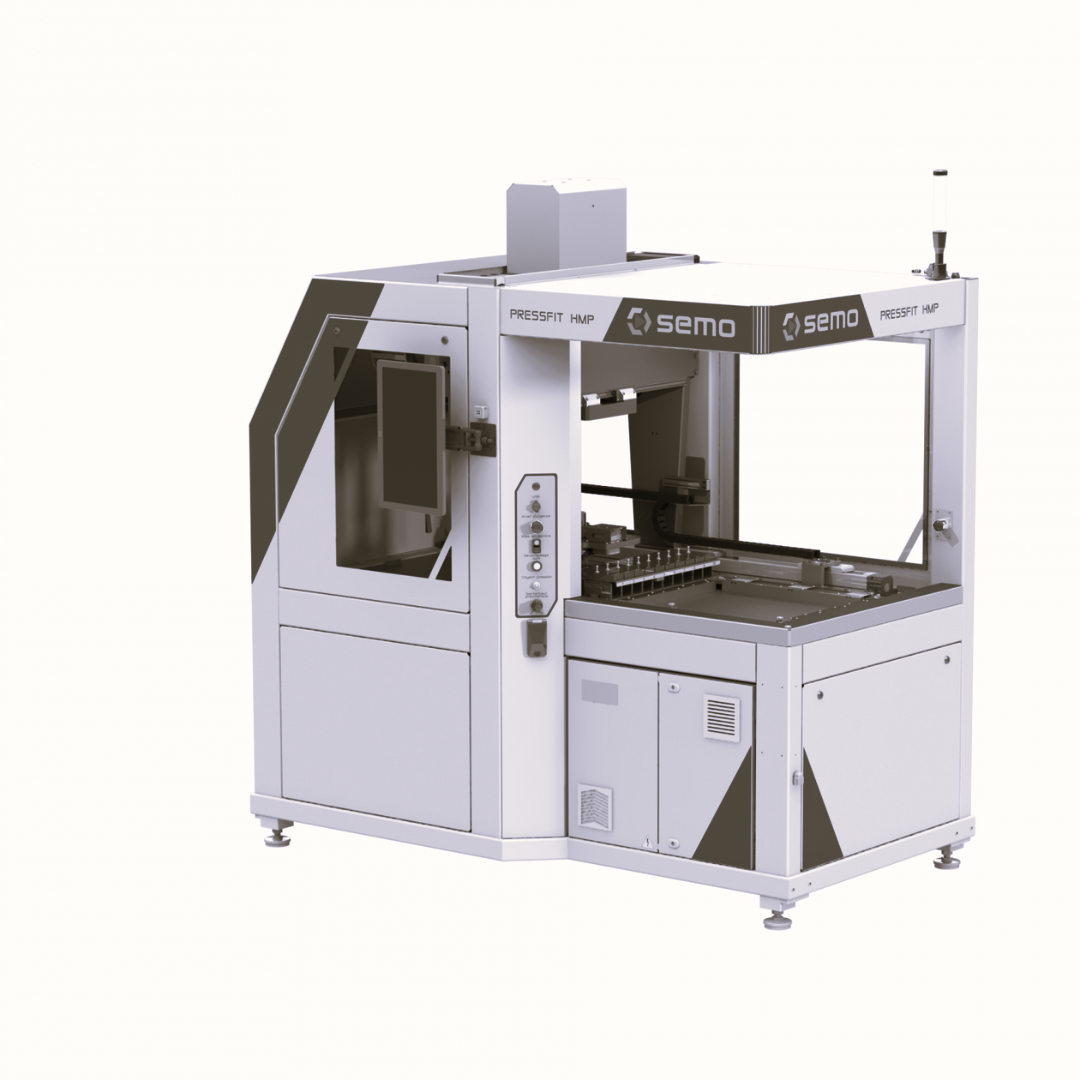

Pressfit-HMP

The high-end, hyper-versatile pressfit

introduction

The HMP pressfit machine is ideal for manufacturers with highly diverse and variable production volumes. The machine can process a wide variety of products independently and with great reliability.

Its optional magazine and fully automatic operation save time and prevent musculoskeletal disorders.

Its Presslink function allows the machine to automatically perform a large part of the programme for a new PCB. The programming operator simply has to specify the pressfit components of their choice and validate the programme.

The strengths of the HMP machine

The HMP machine is designed to deliver the level of quality expected by the most demanding applications. It offers access to press-fit functions during travel or under load. Its design allows for the press-fitting of offset or unstable connectors or terminals, using holding masks if necessary. The surface sensor allows for the management of PCB thickness variability, thereby guaranteeing press-fit quality.

Its digitised axes and optional upper tool magazine save time, reduce risks and enable the automatic production of complete blanks.

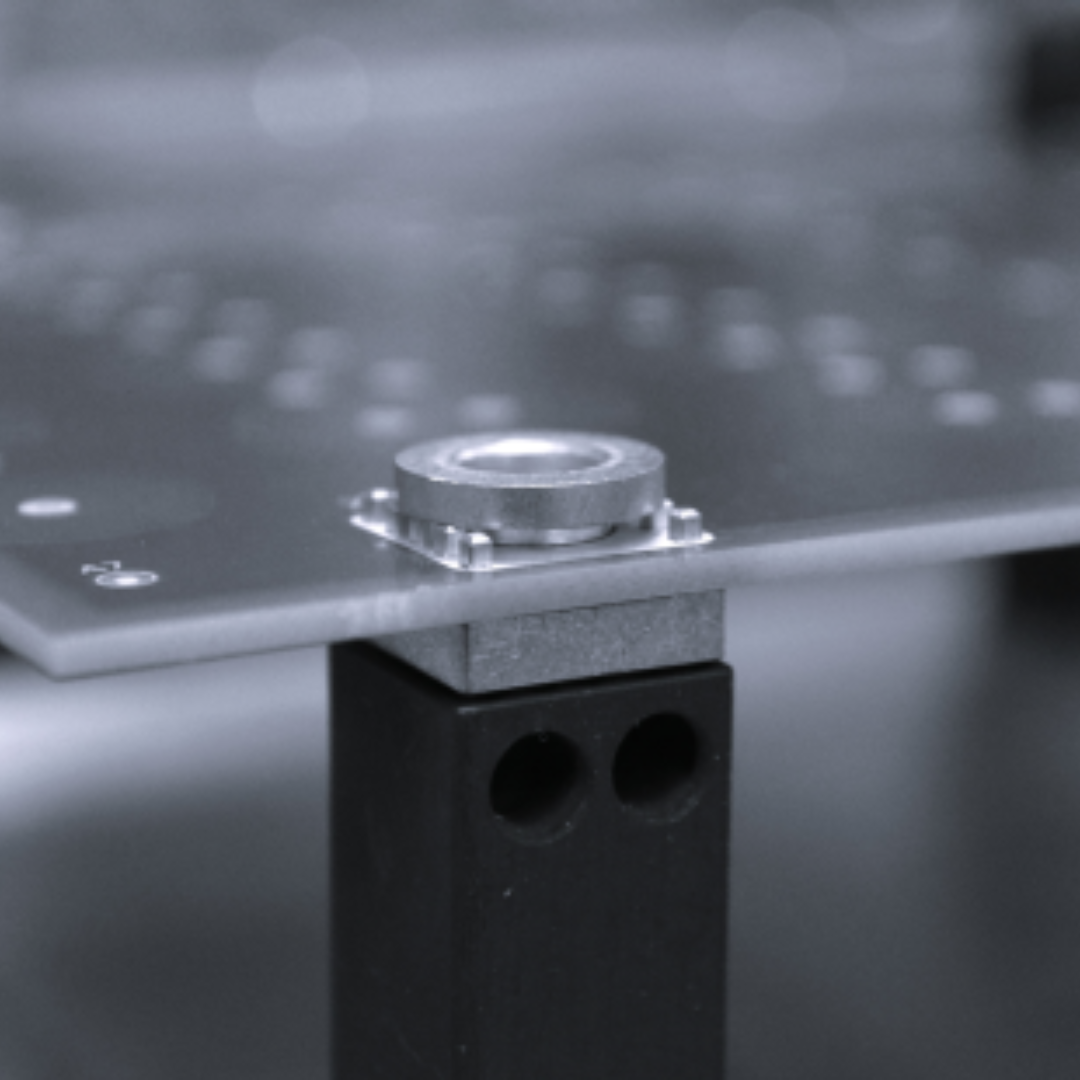

Pressfit from Würth REDCUBE

The HMP pressfit machine can pressfit all components in Würth's REDCUBE terminal range: terminals with internal or external threads, L-shaped terminals that require support during pressfitting, and two-part terminals.

In addition, the HMP press-fit machine can process each side to place the female part first, then the male part, incorporating polarisation to prevent product damage.