Incorporating robotic vision

Combining vision and robotics for greater intelligence.

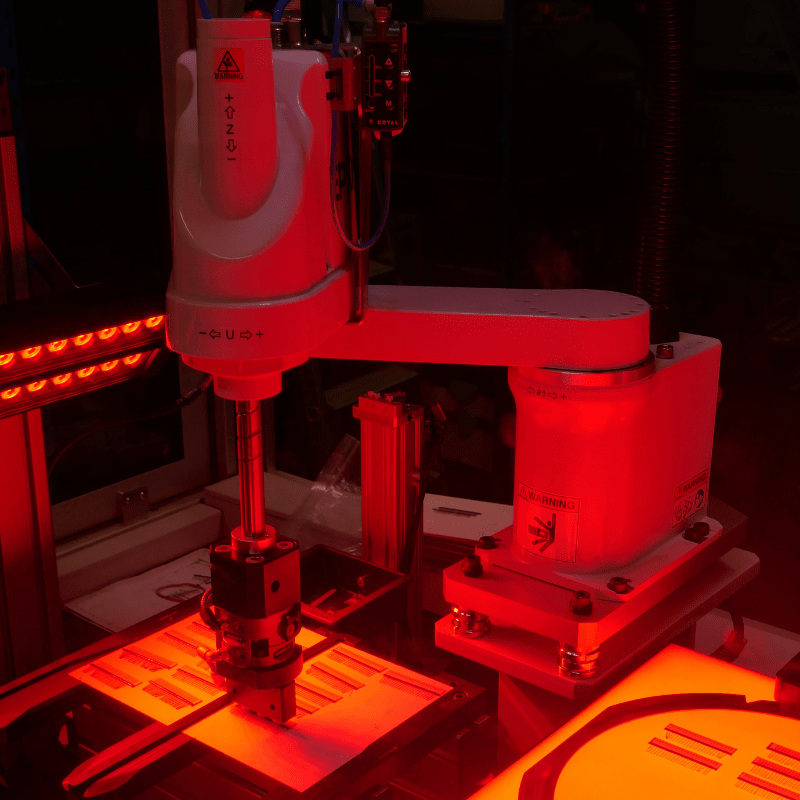

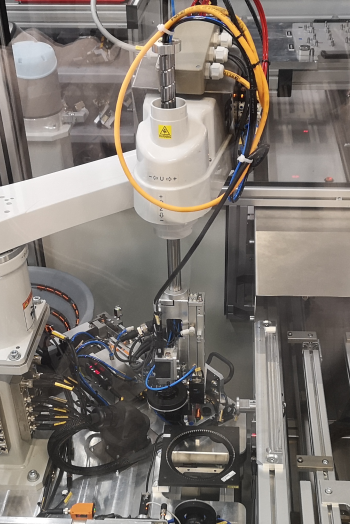

The functions and performances of robots can be greatly enhanced by industrial vision technology which allows repeatable precision control or positioning. The SEMO team is trained in the integration and programming of advanced industrial vision technology.

Why combine vision and robots?

Industrial vision to serve robots

We use industrial vision technology to position robots with the real-time correction of trajectories. This vision technology can be necessary for proper integration, for example for the gripping of parts that are placed randomly on a picking area.

Industrial vision to control

The integration of industrial vision technology in our equipment enables precise control of the position, size, surface, etc of a product or component before, during or after the process. The industrial vision systems implemented by SEMO allow a reliable inspection of the different steps in production thus allowing the improvement in performance by identifying flaws.

Which types of industrial vision technologies do SEMO use?

SEMO is acquainted with the major industrial visions system brands and technologies :

- Code readers (such as Data Matrix or Q-code etc…) which identify serialised products when loaded on the line.

- Vision sensors which allow the simple discrimination between products by their shape or colour.

- More elaborate mono or multi-camera vision systems which can inspect dimensions or aspects of products on a production line. In this case, image processing programs are developped by SEMO.